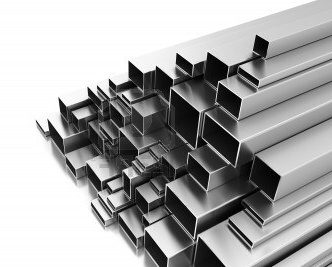

Laser cut thick-wall welded steel frame is the key part of the whole simulator. Premium selected materials and technologies have resulted in strong, flexible and lightweight frame. The frame has been perfectly welded and specially painted to maximize rigidity and the life-time. We have paid attention to the details so the frame does not produce any noises and the surface is almost unscratchable

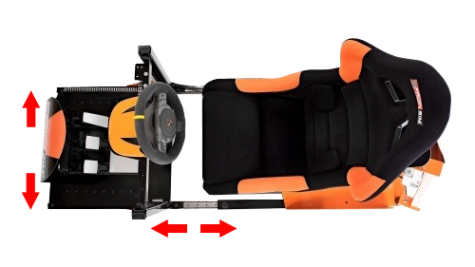

Clever construction allows you to optimize the frame, the seat and all the mounted components according your needs. When it comes to driving, an ideal sitting position and distance from the steering wheel and pedals is extremely important.

Each simulator is individually tested for 20 hours to determine defects and faulty components if any. The specific series of tests focus on every detail such as strength, quality of welded pieces, motion parts, painting, controllers, cables and the other electronics. At the end of the process our technicians set-up the simulator and test it with former professional racers.

The painting is done by powder coating technology. In this process the desired color is first coated on the surface and then baked in high temperature oven. This causes a long life-time and resistance against scratches.

The frame is made out of laser cut thick-wall welded steel of thickness of 3mm (each wall), all parts are perfectly welded together. The component holders for steering wheel, pedals, shifter and other accessories are made out of steel metal of thickness of 5mm. Used materials and technology keep the simulator stable and all the controllers at its positions.

Profisim - Professional Motion Simulators is a producer of professional racing and flight motion simulators. We will convince you of our products quality, so do not hesitate to contact us anytime and join our satisfied customers community. We are ready!